Waste=Value=Profit

We transform one member’s waste into another member’s production process, fueling the circular economy.

By-Product Synergy Network (BPSn):

A By-Product Synergy is formed through the practice of matching undervalued production waste (by-product) to entities that can use this material in their production processes (synergy). Benefits are formed by creating connections.

Revenues for some, savings for others, and valuable business connections (network) for everyone. The benefits to our members come from mutual respect for our planet and sharing its resources.

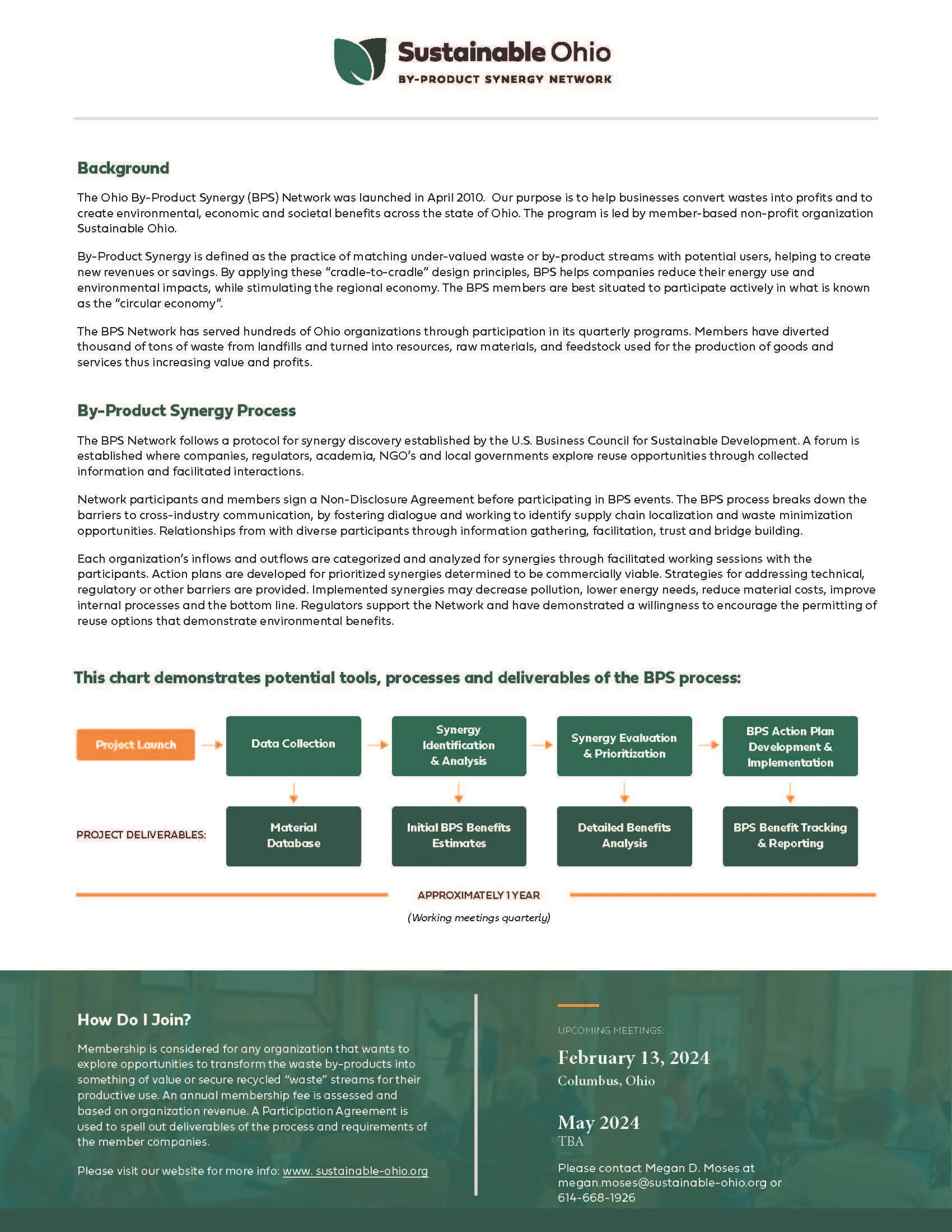

How does it work?

By-Product Synergy: the matching of materials and wasted resources from one facility with potential users at another facility to create new revenues or savings, environmental and societal benefits.

We provide a collaborative network to address sustainability related issues important to member companies.

Provides a structured process through which companies can identify and vet partners

Helps companies identify and implement synergies where wasted resources at one facility are used at another

Provides tools for the management of materials and synergy data

Helps obtain financial resources for implementation

Convene as many organizations as possible, the more present, the better the opportunities:

Networking events and working meetings

Meetings are guided by a documented, step-by-step process. A facilitated process through which members develop relationships and build trust

Members identify and discuss materials, waste and other issues important to their operations

Sustainable Ohio helps members document materials and waste information using a variety of tools and databases

Sustainable Ohio evaluates data and works with members to identify potential by-product synergy opportunities

Download and share our

one page PDF about the organization.

Case Studies

One person’s trash

is another’s business opportunity.

Examples of synergies from prior meetings:

Plastics (including hospital wastes)

Wood (pallets, etc)

Anaerobic Digester/Organics diversion

“Milk Run”; concept of Industrial MRF; aggregation

On-site energy or fuel generation

Dis-assembly or deconstruction

Industrial By-Products

Filter Cake

Micro-enterprise opportunity